Inno-Plast GmbH

Gravimetry

Precise Dosing for Highest Quality Standards

About

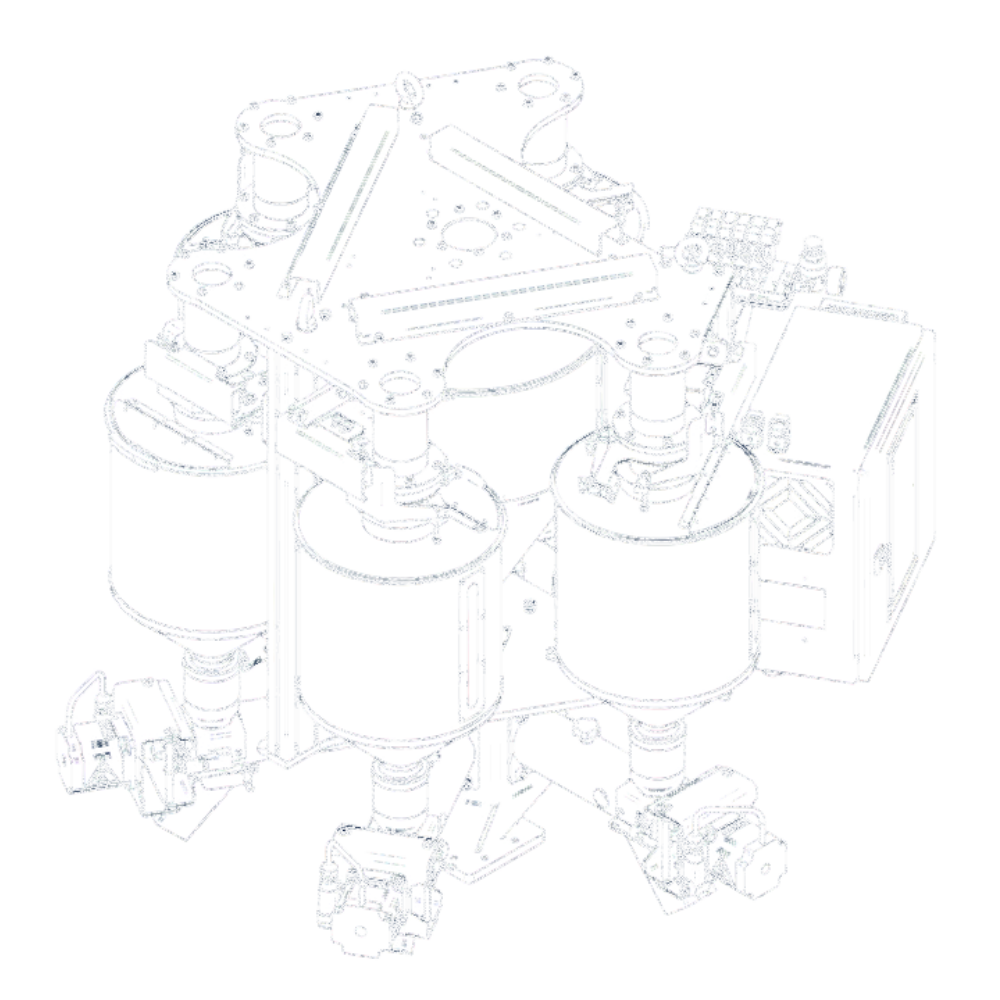

Gravimetry in Plastics Processing

Precise Dosing for Highest Quality Standards

The exact dosing of raw materials is a crucial factor for the quality of plastic products. With gravimetric systems, the material weight can be precisely measured and controlled – for consistent product quality and efficient manufacturing processes.

At Inno-Plast, we rely on gravimetry when it comes to highest accuracy in material feeding. Our gravimetric systems enable precise control of raw material quantities – tailored to your individual production requirements.

For highest demands: Also suitable for food and medical films.

Our Services in the Field of Material Feeding

Precise Material Dosing

With gravimetric dosing systems, we ensure that the exact material quantities are processed – regardless of fluctuations in bulk density or flow behavior. This improves product quality and reduces material losses.

Efficiency and Process Reliability

Through continuous weight control of the fed materials, we increase process reliability. Fluctuations are detected early, corrected, and documented – for consistent production at a high level.

Flexible Integration

Our gravimetric dosing systems can be seamlessly integrated into existing production lines. Thanks to their modular design and compact construction, they can be implemented without extensive reconstruction measures.

Advantages of Gravimetric Dosing

-

Highest Dosing Accuracy

-

Less Material Consumption and Waste

-

Consistent Product Quality

-

Complete Documentation and Control

-

Increased Efficiency and Process Stability

How

How Our System Works

From Silo to Finished Roll

1. Clear Material Management and Silo Level Detection

Our system detects the fill level of your silos in real-time – including precise reporting. This way, you always have an overview of material consumption, batches, and production needs, allowing you to optimize your planning.

2. Automated, Clean Material Feeding

Thanks to our closed conveying technology, the granulate reaches the processing equipment free from contamination. There, the gravimetric system takes over the exact dosing according to the recipe – including regulation of the linear weight (g/m²).

3. Intelligent Real-Time Quality Assurance

Our integrated film thickness measurement, control, and width monitoring guarantee consistently high product quality. All production and quality data are automatically transmitted to the central webMIP system – accessible via browser, mobile device, or as a daily report via email.